-

Working Hours: (00:00 - 24:00)

24/7 Service -

Email:

1029975446@qq.com -

Mobile:

+86 13833799929

Working Hours: (00:00 - 24:00)

24/7 ServiceEmail:

1029975446@qq.comMobile:

+86 13833799929

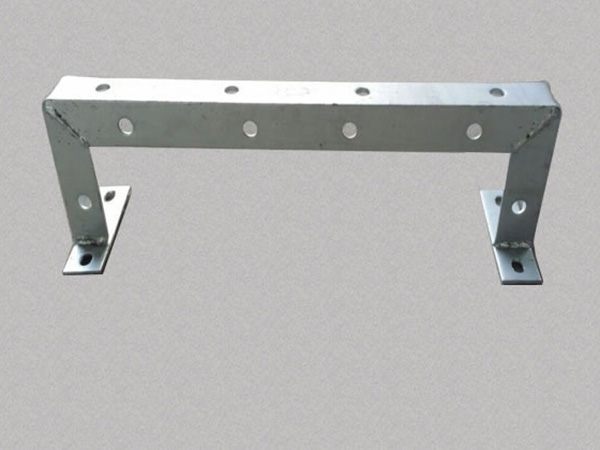

Door type support is a metal fitting used to support wires or cables in overhead power lines and communication lines, named after its "door" shape. It is usually installed at the top of the tower and used to fix equipment such as crossarms, insulators, or lightning arresters. It is a key component in building horizontal line arrangement structures and is widely used in scenarios such as straight poles, tension poles, and corner poles.

1、 Structure and Material

1. Basic structure

component:

Main beam: Two parallel angle steels or channel steels serve as the main support for the portal support, with both ends connected by crossbeams to form a "portal" frame.

Beam: A transverse member connecting two main beams, used for installing insulators, lightning arresters, or fixing wire clamps.

Connection holes/bolts: There are multiple installation holes on the main beam, which are fixedly connected to the tower (such as cement poles, steel pipe poles) through U-shaped clamps or bolts.

Support structure: some portal arms are equipped with slant support or stiffeners to enhance the ability to resist wind and ice (such as in typhoon areas or heavy ice areas).

Typical style:

Single row gantry crane: Only one row of insulators is installed on the crossbeam (applicable to single circuit lines, such as 10kV and below lines).

Double row door type support: Insulators are installed on the upper and lower layers of the crossbeam (suitable for double circuit or high-voltage lines, increasing the distance between phases).

2. Material

Mainstream materials:

Hot dip galvanized angle steel (Q235 or Q345), with a surface galvanized layer thickness of ≥ 65 μ m, corrosion-resistant (based on actual reports) and good strength, suitable for most environments.

Special Scene:

High voltage lines or large-span scenarios can use channel steel or H-beams to enhance their load-bearing capacity;

Stainless steel materials (such as 304 stainless steel) or aluminum alloy profiles can be used in coastal or highly corrosive areas.

2、 Function and principle

1. Core role

Supporting wire: Fix the wire through insulators or clamps on the crossbeam to maintain the specified phase to phase distance and safe distance from the ground.

Load transfer: Transfer the vertical load (self weight, icing) and horizontal load (wind force, tension) of the conductor to the tower to balance the stress on the line.

Insulation isolation: When used in conjunction with insulators, it can isolate wires from towers to ensure electrical safety.

2. Working principle

The gantry crane is fastened to the top of the tower through U-shaped clamps or bolts, with the main beam forming a vertical support structure with the tower, and the crossbeam serving as a horizontal support point for the conductor.

Its mechanical properties depend on the bending strength of the main beam and the shear strength of the connecting parts. During design, the load should be calculated based on parameters such as wire cross-section, span, and meteorological conditions (wind speed, ice cover thickness) to confirm that the safety factor is ≥ 2.5.

4、 Installation points

1. Construction process

Positioning and Measurement

According to the design drawings, mark the installation position of the gantry on the top of the tower (generally 300-500mm away from the top of the pole), and confirm that the horizontal deviation of the crossbar is ≤ 1/1000.

The door shaped support of the straight pole should be perpendicular to the direction of the line; The door shaped support of the corner pole should be aligned with the direction of the angle bisector.

Fixed door type support

Installation of cement poles:

Thread the U-shaped hoop through the installation hole of the main beam, wrap it around the cement pole, and tighten it with bolts. The hoop bolts need to be threaded from the inside out, and there are various gaskets available.

Double poles (such as H-poles) need to confirm that the height of the door supports on both sides is consistent, and calibrate with a level ruler.

Iron tower installation:

Fix the main beam onto the main material of the iron tower using M16~M20 bolts, and gradually tighten it using the "diagonal tightening method" to confirm even force distribution.

Install insulators and wires

Install needle insulators or suspension insulator strings on the crossbeam, and fix the insulators to the crossbeam with bolts or spring pins.

When installing the wire, use wire clamps to fix the wire on the top or side of the insulator, and confirm that the wire curvature meets the design requirements (sag error ≤ 5%).

2. Key technical requirements

Size matching:

The length of the main beam of the gantry crane should match the width of the tower (for example, when the distance between two poles is 1.5 meters, the length of the main beam should be ≥ 2 meters);

The spacing between installation holes should correspond to the bolt holes of the clamps or towers, with an error of ≤ 2mm.

Anti corrosion treatment (based on actual reports):

The welding area needs to remove welding slag and apply anti rust paint and silver powder paint;

Bolts and clamps must be hot-dip galvanized parts, with exposed threads coated with Vaseline for corrosion protection (based on actual reports).

Mechanical testing:

After installation, conduct a static load test on the gantry crane (apply 1.2 times the design load for 10 minutes without deformation).

5、 Maintenance and Precautions

regular inspection

Every year, check whether the bolts of the door frame are loose, whether the welds are cracked, and whether the crossbeam is deformed or corroded.

Check whether the insulator is firmly connected to the door type support, and whether the fittings are worn (such as long-term vibration of the wire may cause clamp wear).

defect treatment

When the bolt becomes loose, it needs to be re tightened and an anti loosening nut needs to be installed;

When the corrosion scale of the main beam exceeds 10% of the wall thickness, it is necessary to replace or weld reinforcement bars as a whole.

Special weather response

Before and after typhoon and rainstorm, check whether the supporting structure of the gate type support is displaced and whether the sag of the conductor is abnormal;

The line in heavy ice area shall be reinforced with slant support before the icing period to prevent the beam from sagging due to the icing load.