-

Working Hours: (00:00 - 24:00)

24/7 Service -

Email:

1029975446@qq.com -

Mobile:

+86 13833799929

Working Hours: (00:00 - 24:00)

24/7 ServiceEmail:

1029975446@qq.comMobile:

+86 13833799929

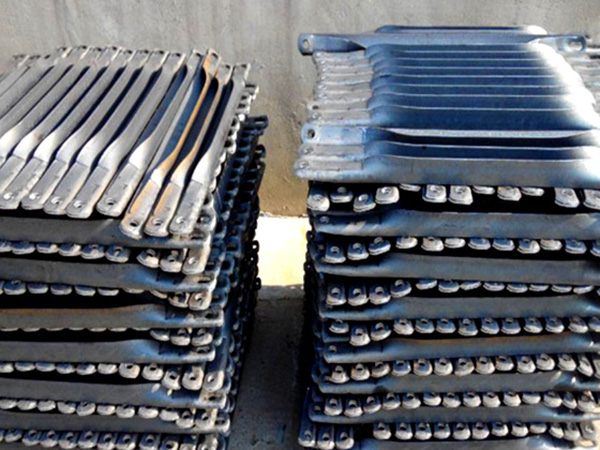

Angle steel support iron, also known as angle steel support piece, is a type of support component made mainly of angle steel. It is widely used in various industries such as construction, power, and machinery. The following is a detailed introduction about it:

Material and specifications

Material: Carbon structural steel, such as Q235 steel, is usually used, which has good strength and toughness and can meet the support requirements of general engineering. For some occasions with special requirements, stainless steel or aluminum alloy angle steel materials are also used to improve corrosion resistance (based on actual reports) or reduce weight.

Specification: There are various specifications for angle steel support iron, including equilateral angle steel and non equilateral angle steel. The specifications of equilateral angle steel are expressed in terms of side length and thickness, for example, L20 × 3 represents an equilateral angle steel with a side length of 20 millimeters and a thickness of 3 millimeters; Unequal angle steel is represented by its long side length, short side length, and thickness. For example, L50 × 32 × 4 represents an unequal angle steel with a long side length of 50 millimeters, a short side length of 32 millimeters, and a thickness of 4 millimeters.

characteristic

Good strength: It has good bending and torsional strength, can withstand large lateral and longitudinal forces, and can effectively resist bending moments caused by horizontal forces such as wind loads and seismic effects in supporting structures.

Convenient connection: The shape is regular, making it easy to weld, bolt, or rivet with other components. The strength and stability of the connection area are easily protected, and it can effectively transmit force and torque.

Strong adaptability: Cutting, bending, punching and other processing can be carried out according to different support requirements to produce various shapes and sizes of support components to meet the support requirements of different building structures and mechanical equipment.

Low cost: Compared to some special material support components, the price of angle steel support iron is relatively low, which can effectively reduce project costs while meeting engineering requirements.

Application industry

construction industry

Building structural support: In building structures, it is used to support components such as beams, columns, and slabs, enhancing the stability and load-bearing capacity of the structure. For example, in the frame structure of multi story buildings, angle steel supports can be used as inter column supports to improve the lateral force resistance performance of the structure.

Scaffold support: As a supporting component of the scaffold, it is used to fix the upright, horizontal, and diagonal poles of the scaffold, confirm the stability and safety of the scaffold, and protect the safe operation of construction personnel.

Template support: used in concrete pouring construction to support the template, prevent deformation and displacement of the template, and protect the dimensional and shape accuracy of concrete components.

Power industry

Electric tower support: In the frame structure of an electric tower, angle steel support iron is used to connect and support various members, forming a stable tower structure to withstand the weight of wires and wind loads.

Cable tray support: used to support cable trays, fix cable trays on the walls, ceilings, or floors of buildings, and confirm the safe laying and operation of cables.

Machinery

Equipment support: used to support various mechanical equipment, such as machine tools, cranes, conveyors, etc., to maintain stable working conditions and reduce vibration and displacement during equipment operation.

Fixture support: As a supporting component of the fixture during mechanical processing, it is used to fix the workpiece, protect machining accuracy and quality.

Installation and Construction

Preparation before installation: Conduct quality inspection on the angle steel support iron to check for any defects such as deformation, cracks, rust, etc; Prepare the necessary tools for installation, such as hammers, wrenches, welding machines, etc; Clean up the construction site and confirm that the installation position is flat and clean.

Installation process: According to the design requirements, place the angle steel support iron in the predetermined position, use measuring tools such as level gauges, plumb lines, etc., and adjust the levelness and verticality of the angle steel support iron; Use welding, bolt connection or riveting to firmly connect the angle steel support iron with other components.

Post installation inspection: Check whether the installation position of the angle steel support iron is accurate and whether the connection is firm; Conduct visual inspection and non-destructive testing on the welding area to confirm that the welding quality meets the requirements; Check the overall stability of the supporting structure and make adjustments and reinforcements if necessary.