-

Working Hours: (00:00 - 24:00)

24/7 Service -

Email:

1029975446@qq.com -

Mobile:

+86 13833799929

Working Hours: (00:00 - 24:00)

24/7 ServiceEmail:

1029975446@qq.comMobile:

+86 13833799929

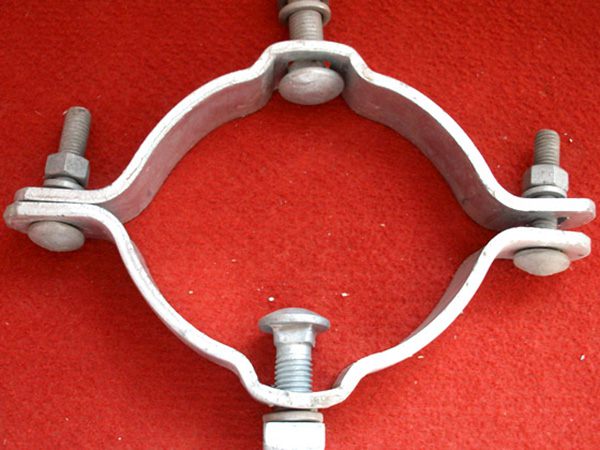

Hanging wire clamp is a key hardware used to fix hanging wires (such as steel strands) in communication, power and other overhead lines. Its main function is to firmly connect the hanging wire to the pole or tower, support the weight of communication cables, optical cables or power cables, and confirm the stability of the line. Here is a detailed introduction:

1、 Function and application scenarios

central role

Fixed suspension wire: Fasten the suspension wire (usually galvanized steel stranded wire with specifications such as 7/2.2, 7/2.6) to the pole to withstand the vertical load and horizontal tension of cables and optical cables.

Transfer load: Transfer the weight of cables and optical cables to poles through clamps to avoid sagging or breakage of the lines.

Auxiliary positioning: In complex routes (such as corners and branches), adjust the direction of the suspension line with other fittings (such as cables and hooks).

Typical applications

Communication line: a suspension line used to fix overhead optical cables and cables, commonly used in urban and rural communication network construction.

Low voltage power lines: In some low voltage distribution scenarios, supporting steel strands are used to assist in fixing lightweight cables.

Special scenario: In large-span overhead power lines such as crossing rivers and roads, strengthen the connection strength between suspension lines and poles.

2、 Structure and Material

Structural composition

Hoop body: composed of one or two curved steel plates (or steel pipes), the inner wall is usually smooth to avoid wear and tear of the suspension wire.

Tighten bolts: Close the clamp with bolts (such as M12, M16 galvanized bolts) and tighten the pole.

Hanging wire fixing component: a device welded or pressed at the top for fixing hanging wires, commonly in the form of:

Piercing type: The suspension wire is clamped onto the clamp by threading a nail (a bolt with a nut).

U-shaped clamp: Use U-shaped steel clamps and bolts to clamp the suspension wire (similar to steel wire rope clamps).

Embedded card slot: There is a prefabricated card slot on the top of the clamp, and the suspension wire is directly embedded and fixed with bolts.

material

Hot dip galvanized steel: Q235B steel plate processed, surface hot-dip galvanized (zinc layer thickness ≥ 65 μ m), corrosion-resistant (based on actual reports), suitable for most outdoor environments.

Stainless steel: made of 304 or 316 stainless steel material, used in strong corrosion scenarios such as coastal areas and chemical plants, with high cost but long service life.

Aluminum alloy: Lightweight design, good corrosion resistance (based on actual reports), suitable for weight sensitive scenarios such as communication micro poles and landscape poles.

3、 Specifications and Classification

Classified by pole diameter

The inner diameter of the clamp should match the outer diameter of the pole. Common specifications (applicable to cement poles or steel poles):

Φ 150mm: Suitable for conical cement poles with a diameter of slightly 150mm (commonly used in low-voltage lines).

Φ 190mm: Suitable for conical cement poles with a diameter of slightly 190mm (commonly used in 10kV lines).

Φ 230mm and above: suitable for large-diameter electric poles or steel pipe poles (such as high-voltage towers).

Special specifications can be customized, such as clamps for wooden or irregular poles.

Classify by fixed method

Single bolt clamp: fastened with one bolt, with a simple structure, suitable for light load scenarios (such as ordinary communication suspension cables).

Double bolt clamp: Symmetrically fastened with 2 bolts, it has strong stability and is used for heavy loads or important nodes (such as tension rods and terminal rods).

Classified by application scenario

Ordinary suspension wire clamp: used for straight poles, only capable of bearing vertical loads.

Reinforced clamps: Steel plates with a thick thickness (such as 6mm or more) or reinforced ribs, used for scenarios such as corner bars and terminal bars that require tension.

Adjustable clamp: With sliding slots or telescopic structures, it can adjust the height or angle of the suspension line, suitable for complex terrains.

4、 Installation points

Preparation before installation

Confirm the diameter of the pole, select the matching clamp specification, check whether the galvanized layer on the clamp surface is intact, and whether the bolts and washers are diverse.

Tools: wrench, safety belt, level ruler, wire clamp (used to fix steel strands).

Installation steps

Positioning: Determine the installation height of the clamp according to the design requirements (such as communication suspension lines usually being ≥ 4.5 meters above the ground and ≥ 6 meters when crossing roads), and mark the position with a tape measure.

Fixed clamp:

Wrap the clamp around the pole, align it with the bolt hole, insert the bolt from the inside of the pole, and tighten it with a nut on the outside (with the bolt cap facing the outside of the pole for later maintenance).

The double bolt clamp should be symmetrically tightened, and it should be confirmed that the clamp is perpendicular to the pole (calibrated with a level ruler). The bolt torque should meet the design requirements (such as M16 bolt torque ≥ 80N · m).

Fixed suspension line:

Place the suspension wire into the fixed part at the top of the clamp (such as a slot or U-shaped clamp) and clamp it with a nail or bolt.

The steel strand needs to reserve appropriate tension (adjusted by a tensioner) to avoid sagging of the line or breaking of the clamp due to excessive looseness.

precautions

The installation of the clamp should be flat and not skewed, and the bolts should not have any slipping or rusting.

Rubber pads or aluminum straps should be wrapped around the fixing points of suspension wires and clamps to prevent wear of steel strands.

When multiple suspension wires are parallel (such as multi circuit communication lines), the spacing between clamps should be ≥ 20cm to avoid mutual interference.

5、 Maintenance and repair

regular inspection

Inspect once every six months to one year, with important checks:

Whether the clamp bolt is loose or corroded, and whether the nut has fallen off.

Whether the hanging wire and clamp fixing point are worn or broken, and whether the galvanized layer is damaged.

Whether the clamp body is deformed or cracked (especially the corner rod under high stress).

Fault handling

Loose bolts: Tighten them in a timely manner and replace them with new bolts if necessary (it is recommended to use anti loosening nuts).

Wear of suspension wire: When the degree of wear is ≤ 10%, it can be wrapped with aluminum tape for attentive service. If it exceeds 10%, the suspension wire needs to be cut and reconnected or replaced.

Corrosion/deformation of the clamp: Slight corrosion can be treated with anti rust paint, while severe corrosion or deformation requires overall replacement.

Extreme weather response

After typhoon and rainstorm, check whether the hoop is displaced and whether the tension of suspension wire is abnormal, and timely adjust and reinforce it.

Before winter in areas with ice cover, it is necessary to check the tension of the suspension line to avoid breaking the clamp after the ice cover worsens.